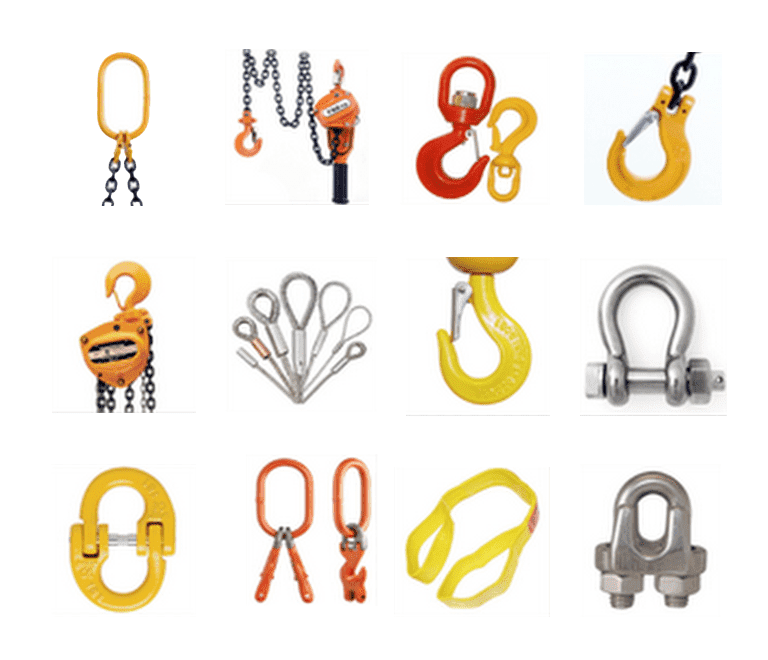

Lifting Tackles

Lifting Tackles

LIFTING SLINGS

Check and ensure that the outer sheaf is not damaged or split, if you can see the inner core then the sling must not be used and must be removed from site immediately.

Check and ensue that the entire sling is free from splits or excessive wear check the ends to ensure no damage or wear. Check and ensure that the sling is not contaminated with oil or chemicals.

GENERAL SAFETY

Store all lifting equipment in a dry area. Once used check the equipment for damage and place back in the storage area. When calculating the required SWL take into account the included weight of slings, hoists, etc. Make sure the ultimate suspension point has an adequate SWL rating. Ensure you have the correct safe working load, check tags, labels, plates or markings.

SLINGER

Check the condition and determine the weight of the load, decide the correct method of lifting and moving the load. Check the route and the stacking area are clear, direct and cooperate with the crane driver to lift, move and position the load. Use the approved code of signals. Select and use the correct lifting tackle, using rules and tables to determine the Safe Working Load (SWL). Visually inspect and check the tackle before use and report any defects.

SLINGERS SAFETY RULES Know the weight of the load to be lifted and ensure it does not exceed the SWL of the tackle and crane. Use only authorized tackle marked with a SWL. Any unmarked tackle must be taken out of service. Inspect all tackle before use. Report damaged tackle which must be scrapped. When lifting with multiple legged slings avoid lifting angles greater than 90’ between legs. Remember that with 3 or 4 legged slings 2 legs may take the majority of the load. Never tie knots in slings or shorten them by wrapping them around crane hooks or using a nut and bolt. Always use the correct pins in shackles and tighten them correctly. Never use rusty wire ropes or fiber ropes that have been in contact with acids or alkalis. Rings and shackles must ride freely on the crane hook. Never lift with the point of the hook. Never put sharp bends in wire ropes. Always protect slings from sharp corners. Never drag slings along the floor. Check that all parts of the load are safely slung. Keep hands clear before lifting and stand clear when the load is lowered. Never stand under a suspended load. Always use bearers to give clearance to allow the removal of slings from beneath loads. When using eyebolts always check they are the correct type for the load and sling. Ensure the threads match and are screwed in firmly. The angle of the sling should not be greater than 15’ from the vertical with collar eyebolts or the SWL will be reduced. Always use the correct signal code. Lifting tackle must be stored correctly, in a clean and dry condition, not on the floor.